ICT and FP Testing

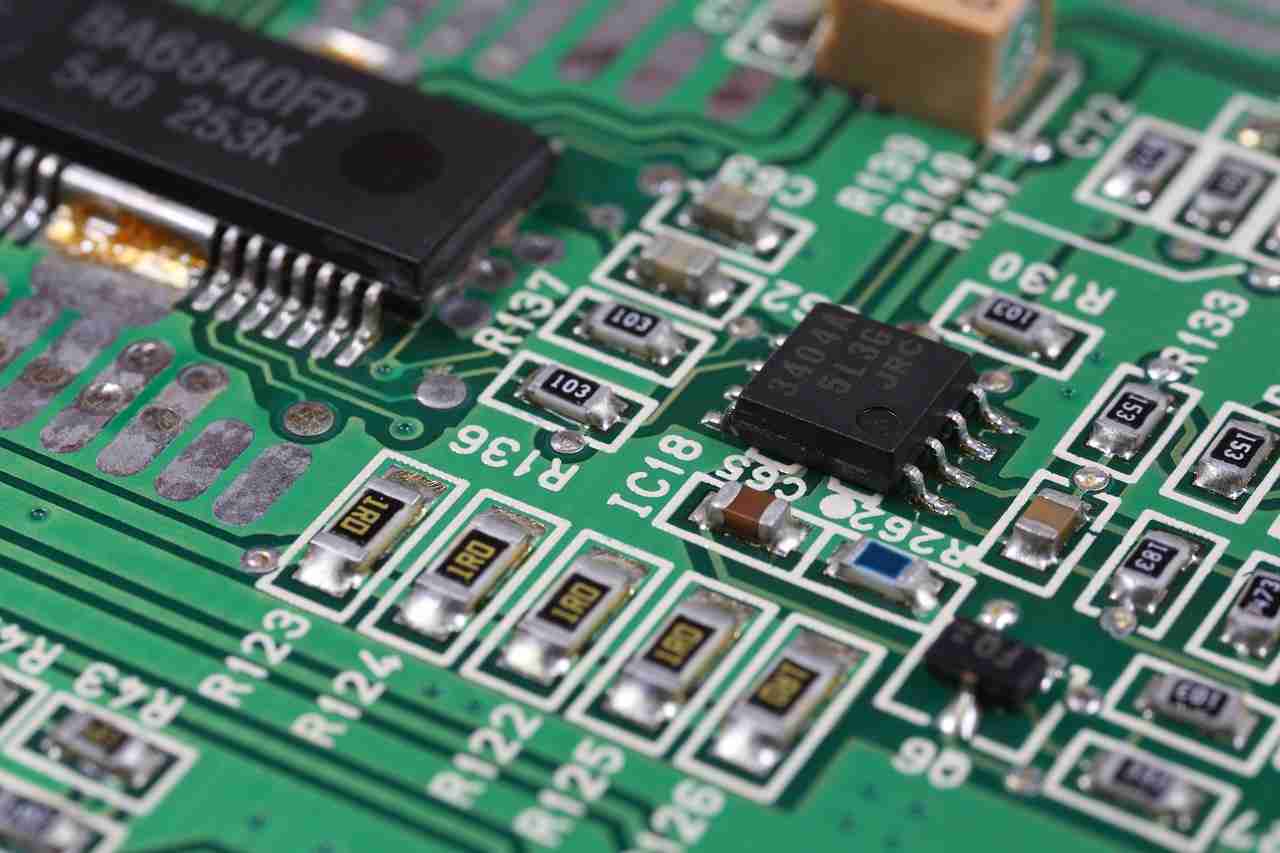

Once we have completed PCB assembly, we test them using ICT or In-Circuit Testing, or FP or Flying Probe testing methods to test for shorts, opens, wrong components, and missing components.

Press-Fit

Using the Press-Fit technology, we can create a connection between the PCB and plated-through holes without soldering them.

Box-Build Assembly

Furthermore, we can also build an electrical device or product by assembling several PCBs along with other electrical and mechanical components.

Conformal Coating

Lastly, we use conformal coating for hermetically sealing components on the PCB. We use acrylic-based coatings to cover the entire PCB assembly. Thus, aerospace and military applications often require conformal coating as protection in adverse environments.