Types of Rush Flex PCB Ceramic PCBs

We make ceramic circuits in various types and configurations, designing them to cater to specific applications and performance requirements. Some common types of ceramic Circuit Boards from Rush Flex PCB are:

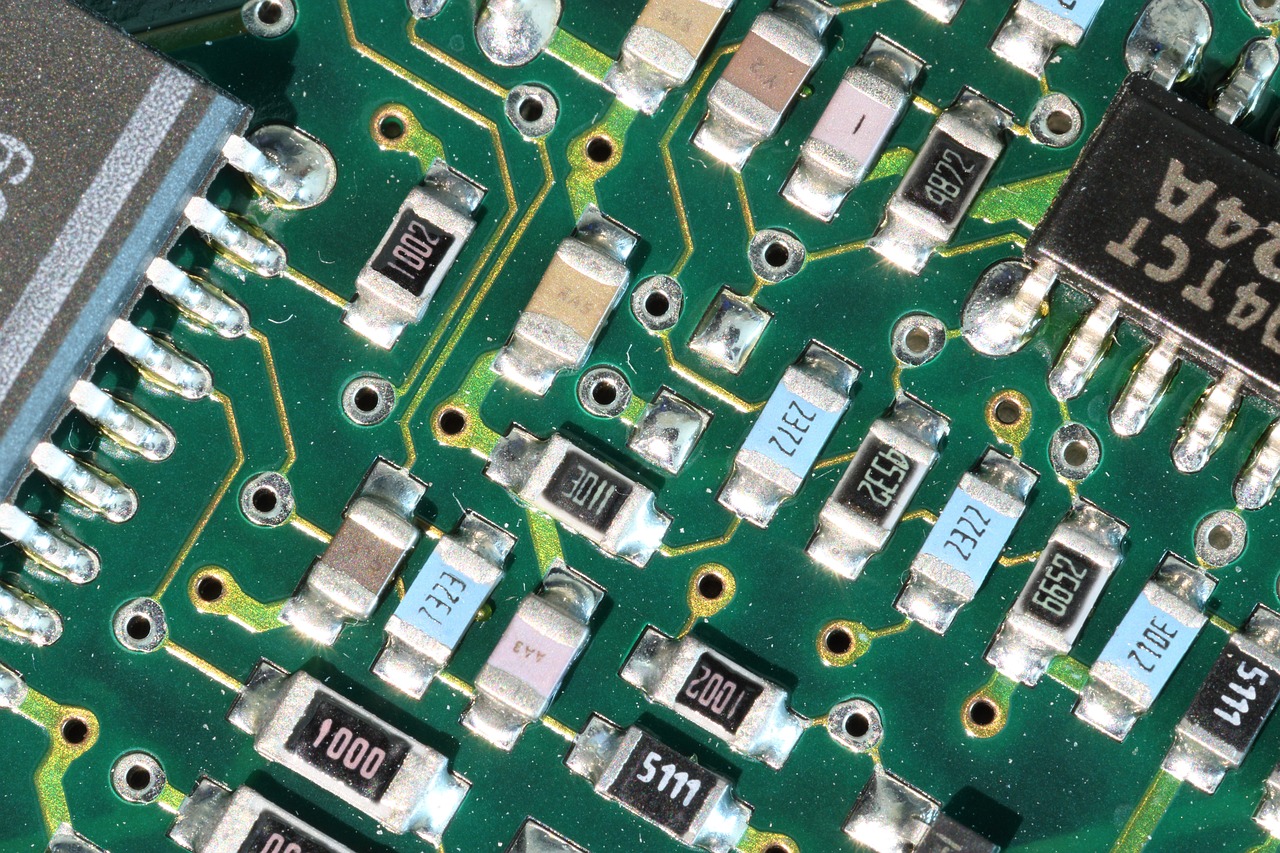

- Single-Layer Ceramic PCB: These are our basic PCBs. They have a single conductive layer on a ceramic substrate. These are often used for simple applications where high thermal conductivity is necessary but without any complex circuitry.

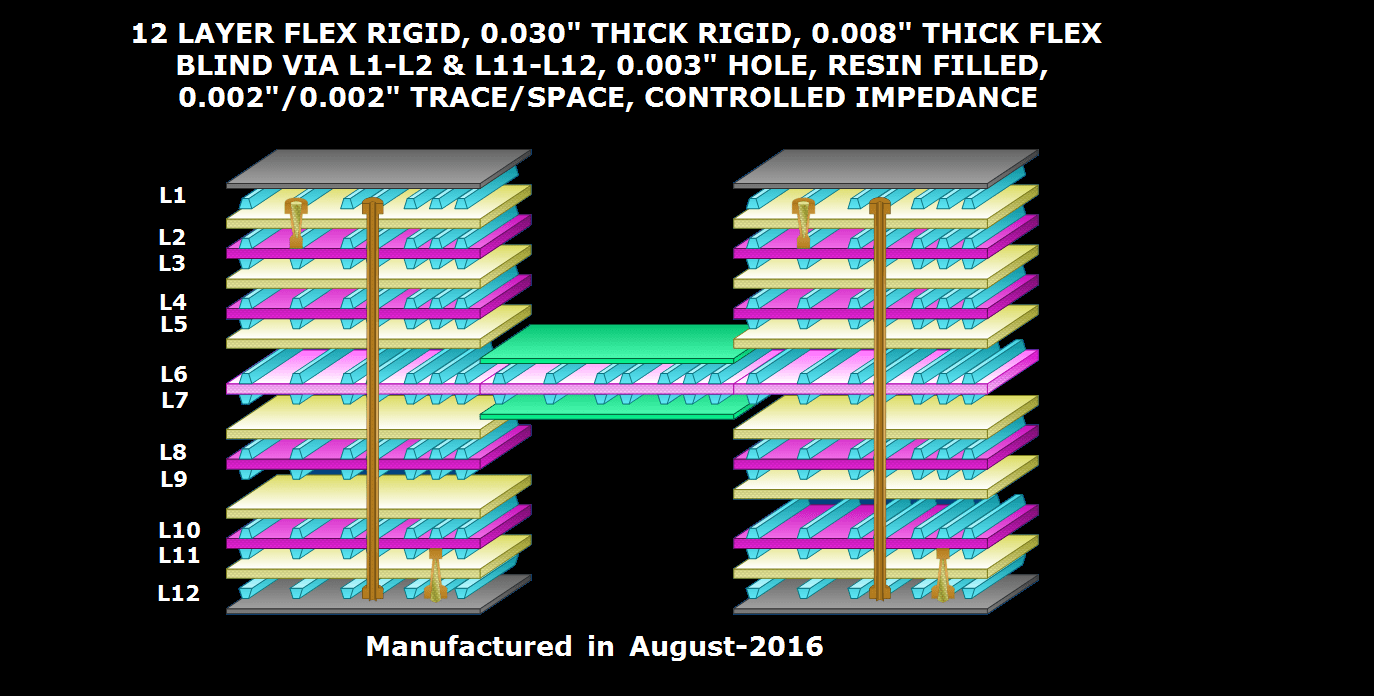

- Multilayered Ceramic PCB: These PCBs are made up of multiple layers of ceramic substrates and conductive traces, with vias interconnecting the various layers. We design our multilayer ceramic Printed Circuit Boards to be suitable for high-density interconnects, complex circuit designs, and applications requiring signal integrity.

- Thick Film Ceramic PCB: For this type, we use thick film technology to create conductive and resistive traces on substrates made of ceramic materials. Hence, these ceramic PCBs are highly durable and suitable for applications in harsh environments like automotive and industrial settings.

- Thin Film Ceramic PCB: For our thin film technology, we deposit thin layers of conductive and insulating materials onto ceramic substrates. Our thin film ceramic PCBs offer accurate electrical properties useful in high-frequency applications, such as RF and microwave devices.

Other Types of Ceramic Circuits Boards:

- Hybrid Ceramic PCB: For our hybrid ceramic PCBs, we combine ceramic materials with different materials like metal cores or organic substrates. So, this hybrid approach balances the benefits of ceramics with the advantages of other materials, such as cost-effectiveness or specific thermal properties.

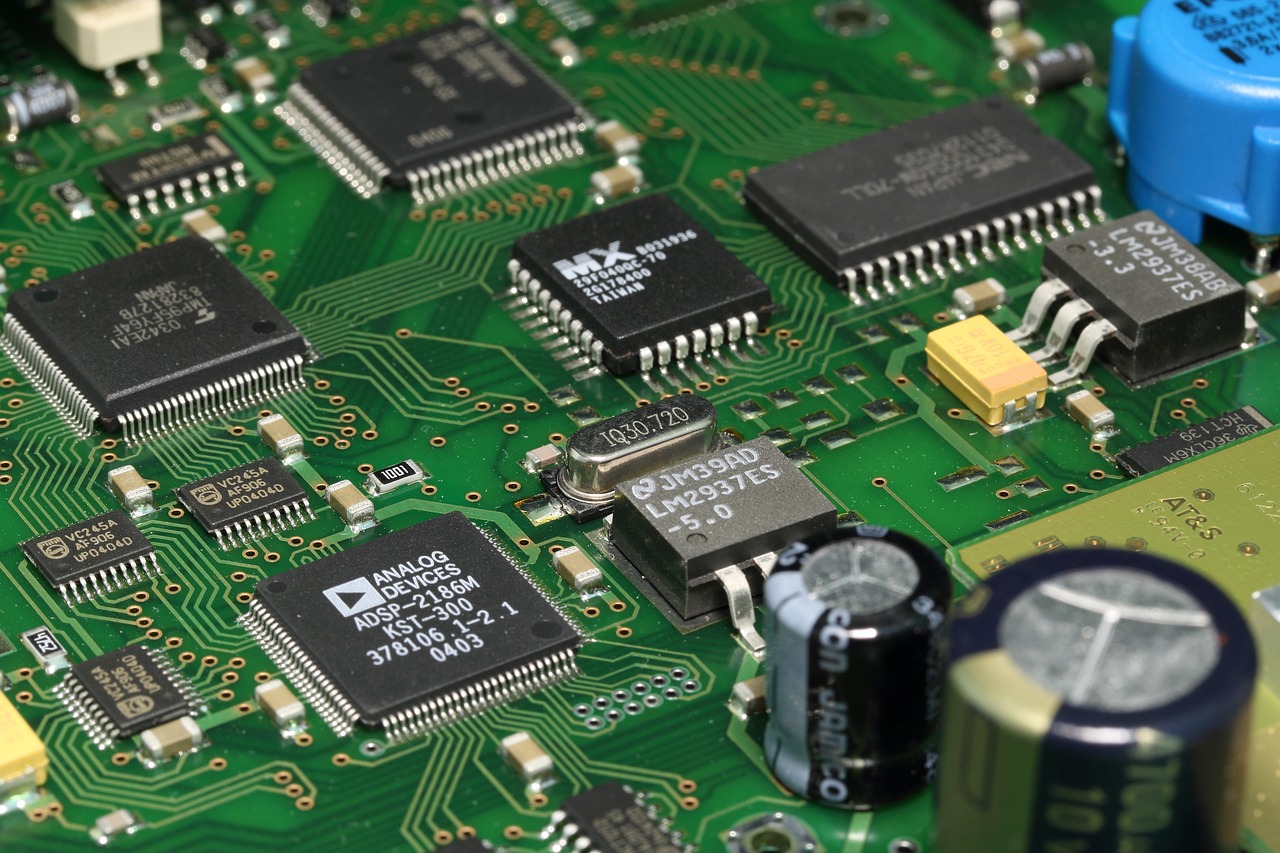

- Al2O3 or Alumina Ceramic PCB: We make our alumina ceramic Printed Circuit Boards from aluminum oxide, and they offer high thermal conductivity, electrical insulation, and mechanical strength. Thus, these are suitable for various applications, including power electronics, LED modules, and high-power RF devices.

- AlN or Aluminum Nitride Ceramic PCB: We offer aluminum nitride ceramic PCBs with much higher thermal conductivity as compared to alumina, thereby making them suitable for applications where efficient heat dissipation is critical. The industry often uses them in high-power electronic devices and LEDs.

- BeO or Beryllium Oxide Ceramic PCB: The special characteristic of our beryllium oxide ceramic Circuit Boards is extremely high thermal conductivity. The industry uses them in applications with efficient heat dissipation demands, such as in high-power RF amplifiers.

- SiC or Silicon Carbide Ceramic PCB: Known for their excellent electrical and thermal properties, including their ability to withstand high temperatures and harsh environments, the industry uses our silicon carbide ceramic Printed Circuit Boards in high-temperature electronics and power electronics.

- LTCC or Low-Temperature Co-fired Ceramic Board: In our LTCC technology, we co-fire many layers of ceramic substrates at low temperatures. The industry uses our LTCC ceramic PCBs in RF modules, sensors, and other miniaturized devices.

- HTCC or High-Temperature Co-fired Ceramic PCB: We achieve high-temperature co-firing by mixing aluminum oxide and adhesive, lubricant, plasticizer, and solvent, leading to the roll-forming of the raw ceramics. Moreover, we follow this up with coating and implementing circuit tracing on refractory materials, and firing it at high temperature, baking it for 32–48 hours. Applications include small-scale boards, carrier circuits, and derived boards.

As a leading manufacturer of ceramic printed circuit boards, Rush Flex PCB boasts decades of rich manufacturing and assembly experience. In addition, our high-quality alumina PCBs, aluminum nitride PCBs, LED COBs, DOB LEDs, IGBT ceramic substrate boards, 3D alumina products, and more are in great demand in the electronics industry. Moreover, we provide free design and manufacturing guidance to help you navigate the process. Furthermore, you can benefit from our one-on-one engineering support to bring out the best in your high-quality ceramic circuits.